ProServ is one of Germany’s largest and most modern service providers when it comes to the reprocessing of medical products. The ProServ

portfolio includes a wide range of medical support services, including the cleaning, sterilization and repair of instruments used in

hospitals and clinics.

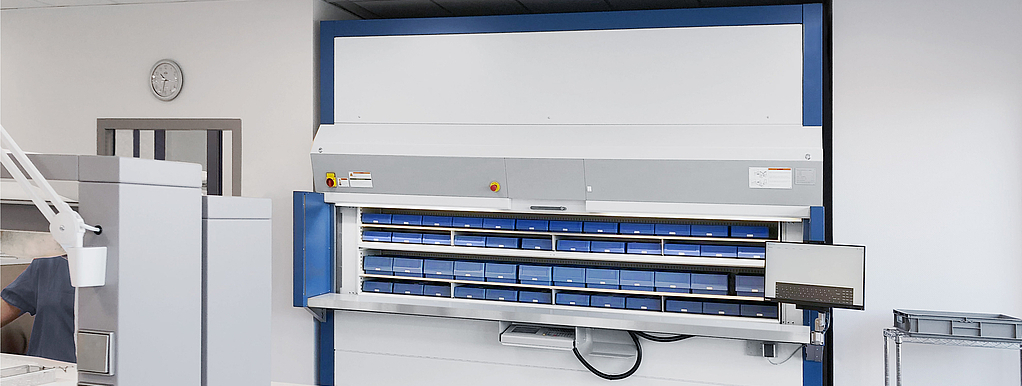

At the company site in Pulheim near Cologne, ProServ operates a Hänel Rotomat® lift system for organizing and storing reprocessed instruments. More than 800 different surgical instruments are kept in this system after they have been reprocessed. In collaboration with INVITEC, a subsidiary of Aesculap, Hänel developed a customized software solution that links the lift system to the sterile goods management software instacount®PLUS. The instacount.LIFT module combines the intuitive use of instacount®PLUS with the fast and ergonomic provisioning of medical products from the Hänel®Rotomat storage lift. The Hänel storage solution is thus completely integrated in the ProServ infrastructure.

ProServ customers can request sterilized instruments as needed by using a booking system. These requests are recorded in instacount®PLUS and are then sent as pick orders to the touch terminal of the storage lift system. When the user selects an order, the Rotomat® storage system brings the requested instruments to the access point quickly thanks to optimized routing. There is no need to confirm the pick on the lift controller because instacount®PLUS is directly linked to the lift system. User safety is ensured even during automated operation thanks to a light barrier curtain positioned just in front of the access point. The Hänel compartment and sub-level indicators show precisely where items are located to ensure error-free retrieval.

Each workplace in the instrument reprocessing area is equipped with an instacount®PLUS terminal so that all job orders can be managed centrally. Employees can thus process pick operations directly on the terminals and request instruments stored in the lift. The sequence of picks can be changed at any time. For example, rush orders can be prioritized and moved up ahead of other orders. This is done intuitively per drag and drop on the terminal touchscreen.

Reliable repair management is another advantage when it comes to instrument reprocessing

Defective surgical instruments can be assigned repair labels which are printed out by instacount®PLUS – the software automatically helps the storage lift system find the storage position which has just the right substitute instrument. If an item in instacount®PLUS is listed as in need of repair, this item position is “locked” and the item cannot be picked from the Rotomat® lift system to fill any orders until the item has been repaired and then officially released for use.

The Hänel Rotomat® lift optimally utilizes the space available at ProServ. The vertical carousel principle of the system provides maximum storage capacity within a minimum footprint and ensures ergonomic operation. The central storage for instrument reprocessing shortens the distances employees need to walk during order picking. The organization inside the lift also effectively reduces the time needed to search for items and ensures high levels of inventory security for reprocessed instruments and medical products.

The Hänel Rotomat® lift is ideal for deployment in sterile environments. Material in the lift is protected against contamination, dust and light. The work counter of the lift is made of stainless steel for easy cleaning and effective disinfection. Special paneling also prevents the accumulation of dirt on the exterior surface of the lift.

The Hänel Rotomat® in combination with instacount®PLUS offers high levels of reliability, storage capacity and ease of use. This intralogistics solution satisfies the stringent requirements governing the fast and error-free provisioning of surgical instruments.